- All Products

- Hubei Lituo Energy - Complete set design, manufacture and installation of tower equipment and tower internals packing

The company collaborates with the School of Chemical Engineering and Technology of Tianjin University and the School of Chemical Engineering and Technology of East China University of Science and Technology in the areas of mass transfer, distillation, and separation for large-scale chemical towers.Currently, our company has achieved the complete set design, manufacture and operation of desulfurization towers with a maximum diameter of DN1200mm, as well as their internal components and packing.

Tower equipment and internal components renovation project: Solving various difficult problems in the operation of tower equipment and internal components in chemical plants

- Increase the processing capacity of the device (from 90T/H to 120T/H).

- Reduce the unit consumption of the device (by 15%).

- Improve the product quality of the device (from 99% to 99.8%).

- Extend the operation cycle of the device (increase the one-time operation cycle from 9 months to 16 months).

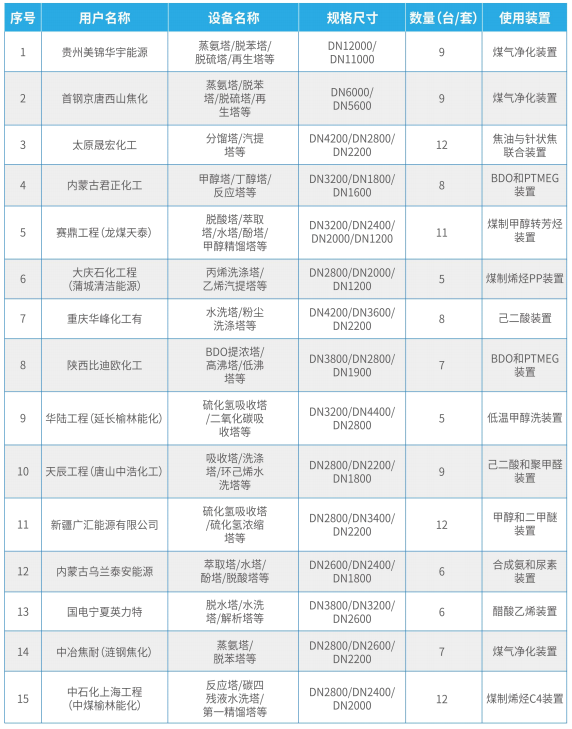

Typical Performance Table of Complete Set Supply of Tower Equipment and Tower Internals Packing

Applicable materials:

Carbon Steel(Q235B,Q245R/Q34R), Stainless Steel(304,316L), Duplex Stainless Steel(2205,2507), 904L, 254smo, Hastelloy, Titanium, Zirconium, etc.

Applicable fields:

Coal chemical industry, coal coking, oil refining and petrochemicals, fine chemicals, fertilizers and pharmaceuticals, metal smelting, new energy materials, battery materials, etc.

Specifications

| Companies | Hubei Lituo Energy Chemical Equipment Co., Ltd. |