- All Products

- Hubei Tianxin Petrochemical - Automatic Oil Cut off and Drainage Valve

Product Introduction

This product utilizes the difference in buoyancy between oil and water based on their varying densities to achieve oil separation and water drainage. When there is water in the silt trap well and it reaches a certain height, the buoyant float rises. With a relatively small force through the lever, the pressure reducing valve can be opened, and the air vent in the drainage valve core is opened. Water flows from the drainage valve into the drainage tank, achieving pressure reduction. The buoyant float continues to rise, opening the drainage valve, and water flows into the drainage tank from the drainage valve. The water is then drained through the drainage tank. When the medium in the silt trap well is oil, the buoyant float sinks. Through the lever, the air vent of the pressure reducing valve core is closed, and the drainage valve is closed. This prevents the leakage of the oil. When the weather is extremely dry and there is no water in the silt trap well, the drainage valve automatically remains closed. When the medium of the drainage system in the oil storage tank area is in an oil-water mixture state, the oil and water separate in the silt trap well. The water at the bottom is discharged through the drainage valve, while the oil is retained in the silt trap well. As long as the oil in the silt trap well is collected, the oil can be extracted. Thus, the complete automation of oil separation and water drainage in the oil storage area is achieved.

Product Features

1. This product adopts a special design structure without back pressure. The lever drives the valve needle to move, ensuring uniform pressure outside the valve core. The lever continues to move, and the needle valve and the valve start to drain water flexibly together, thus solving the problem of the different timing between the pressure reduction valve and the drainage valve, overcoming the defect of poor closure, and ensuring the safety of the irrigation area.

2. It can achieve automatic control without any energy consumption, being safe, environmentally friendly and economical.

3. It is small in size, has a reasonable structure, no vulnerable parts, long service life, does not require supplementary water, and is convenient for use and maintenance.

4. It automatically turns on when there is water, and automatically shuts off when there is no water. When there is a mixture of oil and water, it automatically separates the oil and water. This equipment operates 24 hours a day, reducing the workload on the operators who need to open the valve when it rains and close it when it's sunny, and eliminating the occurrence of oil leakage accidents.

Technical Specifications

1. Nominal diameter: DN200, DN250, DN300, DN350, DN400

2. Nominal pressure: <0.6 - 0.25 MPa

3. Flange standard: HG/T20592-2009

4. Applicable medium density: ≤ 970 kg/m³

Product Type

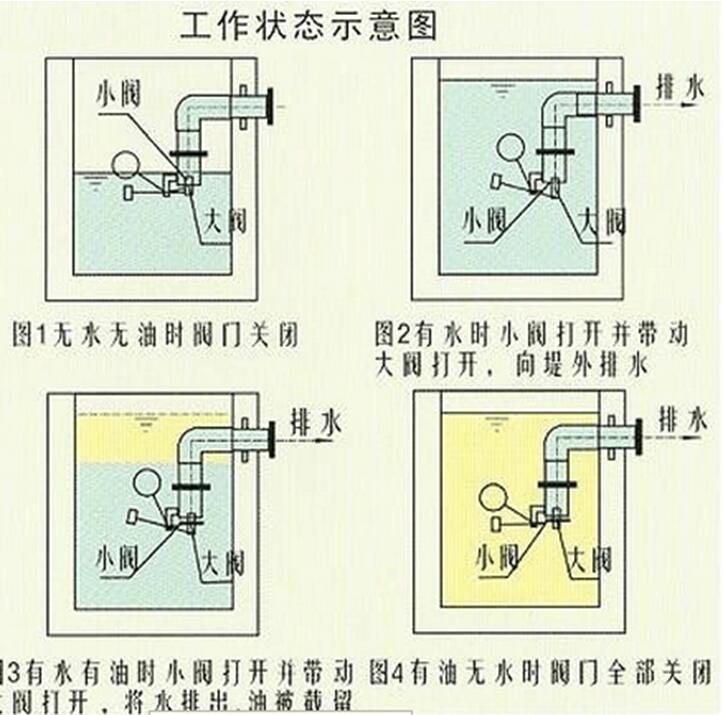

Working diagram of the LTYS-II type oil-blocking and water-discharging device (automatic oil-cutting and water-discharging valve):

Depending on the orientation of the pipe interface, the LTYSⅡ1 type oil-blocking and drainage device (automatic oil-cutting and drainage valve) is divided into two types: Type A and Type B.

Type A is installed with the interface flange vertically, while Type B is installed with the interface flange horizontally.

Product Working Status Diagram

Product Specification Model

Serial Number | Specification Model | Export Size | Remarks |

1 | LTYS-Ⅱ-150 | DN150 | Flange connection, vertical (horizontal) installation |

2 | LTYS-Ⅱ-200 | DN200 | Flange connection, vertical (horizontal) installation |

3 | LTYS-Ⅱ-250 | DN250 | Flange connection, vertical (horizontal) installation |

4 | LTYS-Ⅱ-300 | DN300 | Flange connection, vertical (horizontal) installation |

5 | LTYS-Ⅱ-400 | DN400 | Flange connection, vertical (horizontal) installation |

Specifications

| Companies | Hubei Tianxin Petrochemical Equipment Co., Ltd. |