- All Products

- Hubei Tianxin Petrochemical - Dry Water Heating Heater

Product Introduction

The traditional storage tank heaters are usually of a combined type, consisting of a coil and a tube. Their characteristic is that the input heating medium and the output condensate share the same pipeline. If the heating medium is steam, when the steam reaches the nodes or bends, it will collide with the condensate in the pipeline. Due to the long and thin nature of the heater pipeline, resonance is likely to occur, which will exacerbate the severity of the above phenomenon and lead to the so-called "water hammer" phenomenon. Because water vapor has a strong corrosive effect on carbon steel pipes, and the hydraulic shock waves are very likely to cause perforation and leakage in the heating pipeline, resulting in a significant reduction in the efficiency of the heater or even failure.

The water-free heating device ensures the uniformity of oil heating. The heating tube bundle is installed vertically, allowing the steam passing through the heating device and the condensate water to be fully separated. All the steam entering the heating device is discharged in the form of water, achieving efficient utilization of steam and energy conservation! Moreover, a certain slope is formed in each group of circuits, facilitating the discharge of condensate water, thus eliminating water knock.

Company Background and Product Overview

The storage tank heater is the core production line of Honghu Tianxin Petrochemical Equipment Manufacturing Co., Ltd., integrating R&D, design, and a continuous production line. It is newly designed and manufactured according to the requirements of the tank type and heating area. The main components of the storage tank heater, such as the heating tube bundles and connecting pipes, are all designed and manufactured in the factory. It has the advantages of a short production cycle, advanced equipment, and excellent production environment, which results in a reduction in production costs without compromising quality. After being delivered to the site, all the storage tank heaters are connected by butt welding. The construction unit only needs to weld according to the accompanying drawings. The storage tank heater is made with a completely new design and production process, which effectively increases the product's service life. The service life can reach over 15 years, significantly reducing the main cost.

Scope of Application

Applicable medium range: Heavy diesel, fuel oil, lubricating oil, edible oil, crude oil, wax oil, residue oil, dirty oil, chemical raw materials with high freezing point crude oil, and heating-required storage tanks in cold regions.

Applicable heating media: The imported heating media are water and steam.

Structural Characteristics

1.The heated steam pipeline is separated from the cold condensate discharge pipeline and is used independently.

2. According to the heating area ratio: Set multiple inputs and multiple outputs;

3. Install the steam-water separation plate: Add an enhanced separation processing unit to reduce the moisture carried in the steam and prevent water from being entrained in the steam pipeline.

4. Set up the expansion container

Heating Purpose

Many types of oil have a high viscosity at low temperatures. For some oil containing wax, when the temperature drops, the wax crystals will precipitate and the oil will solidify.

1.Prevent the oil from solidifying;

2. Reduce the hydraulic friction of oil transportation within the pipeline;

3. Accelerate the loading and unloading speed of oil tankers and oil tanks;

4. Remove water and sediment impurities from the oil.

5. Accelerate the blending of oil products and carry out the regeneration of lubricating oil.

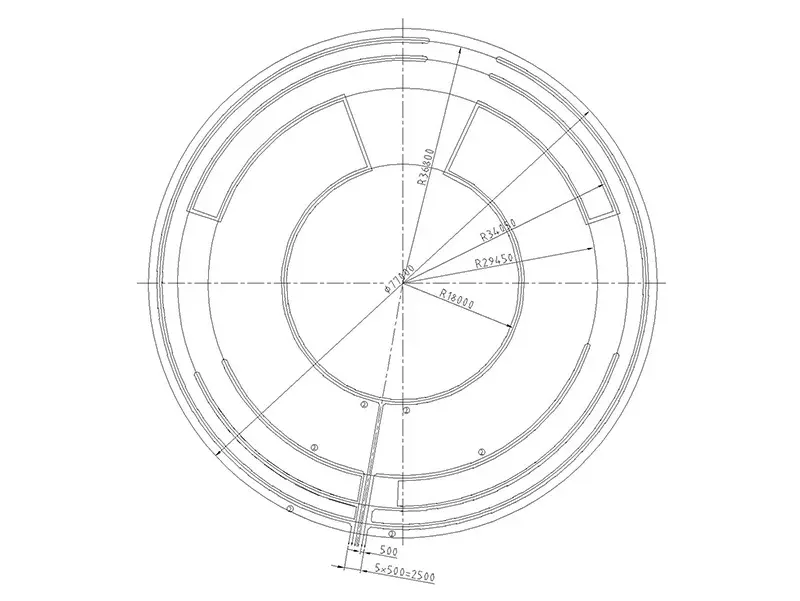

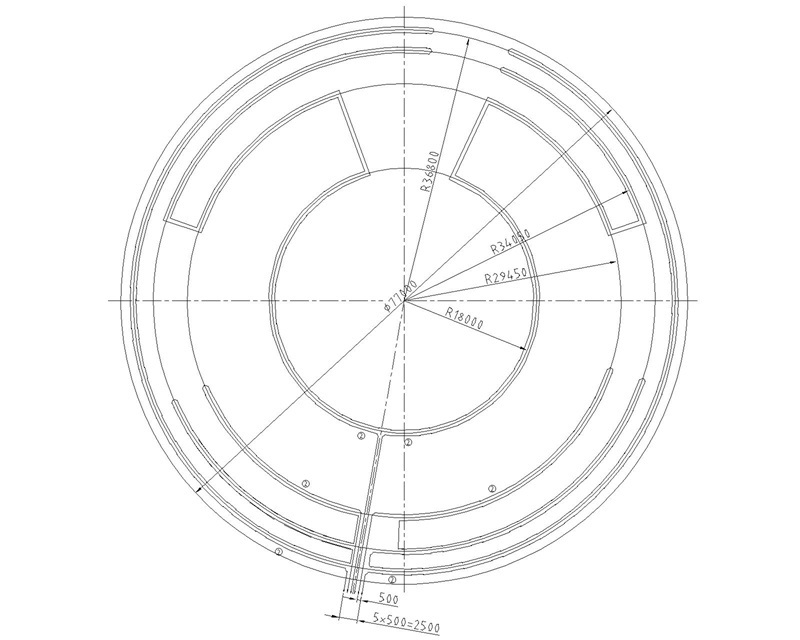

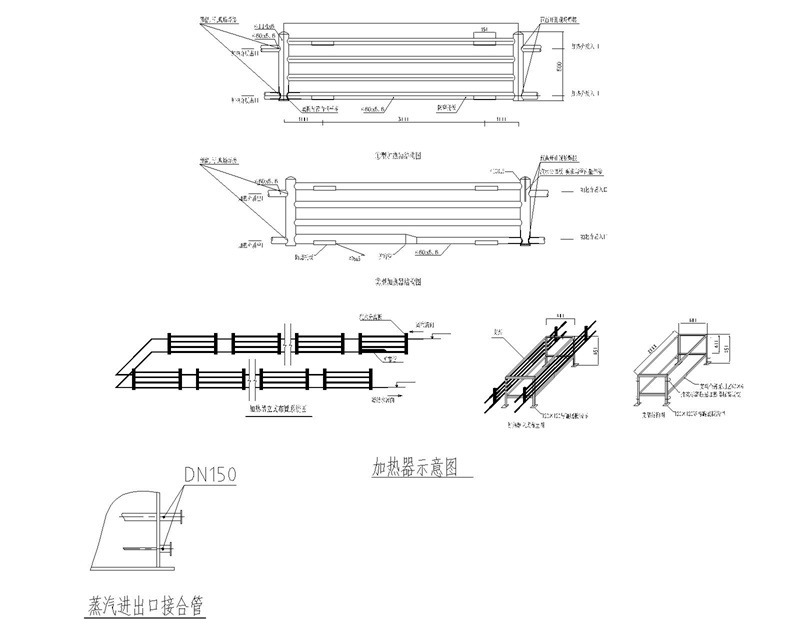

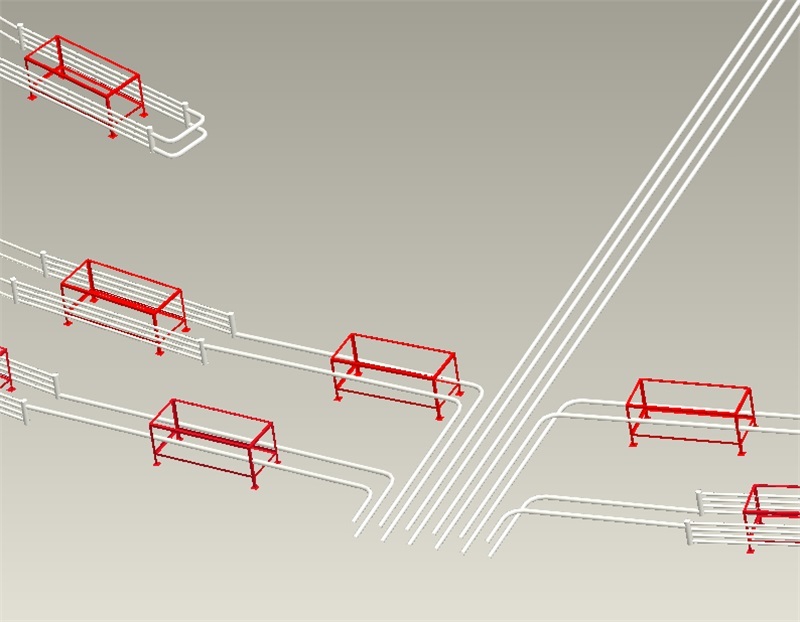

Heater Diagram

Installation diagram of the clamp

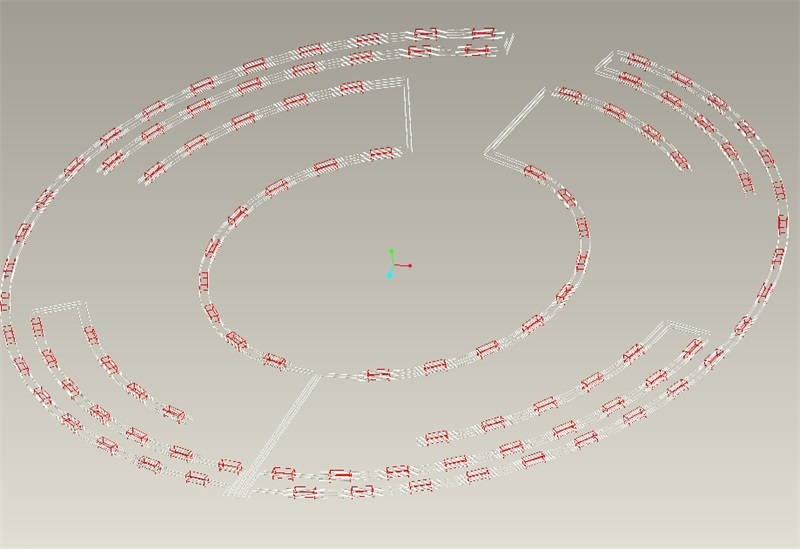

Three-dimensional renderings of the heater's physical appearance

Heater Maintenance and Care

During the daily operation inspection of the heater, attention should be paid to whether there is any oil contamination in the condensate water, and whether there is an increase in water at the bottom of the oil tank, etc. When not in use, the drainage valve should be opened to drain the accumulated water. Before winter arrives, it is necessary to conduct an inspection to eliminate potential hazards.

Specifications

| Companies | Hubei Tianxin Petrochemical Equipment Co., Ltd. |