- All Products

- Hubei Tianxin Petrochemical - Emergency Drainage System

Product Introduction

This product has been awarded a national patent. Currently, the external floating roof oil tanks in the petroleum storage area have been exposed to the outside environment for a long time, resulting in accumulated water on the floating roof, which directly affects their safe operation. Currently, the external floating roof oil tanks use a central drainage system. When there is heavy rain and the central drainage system is blocked or leaks, or when the drainage system cannot be used, a large amount of water on the floating roof will be unable to be drained. Due to the limited capacity of the central drainage system, the drainage effect will be poor.

The emergency drainage device is a component of the floating roof drainage system. Its function is to eliminate excessive water accumulation on the floating roof caused by the failure of the drainage system or other reasons. It directly discharges the excessive rainwater into the tank, preventing the floating roof from sinking or being damaged. The emergency drainage device features smooth drainage, flexible floating of the float ball, and reliable reverse sealing performance.

Company Background and Product Overview

The emergency drainage device is the core production line of Tianxin Petrochemical Equipment Manufacturing Co., Ltd. in Honghu City. It integrates an outstanding R&D team, design, and a continuous production line. It is developed and produced based on market requirements. The emergency drainage device is all designed and manufactured in the factory. It has the advantages of a short production cycle, advanced equipment, and excellent production environment, which results in a reduction in costs without compromising quality.

Working Principle

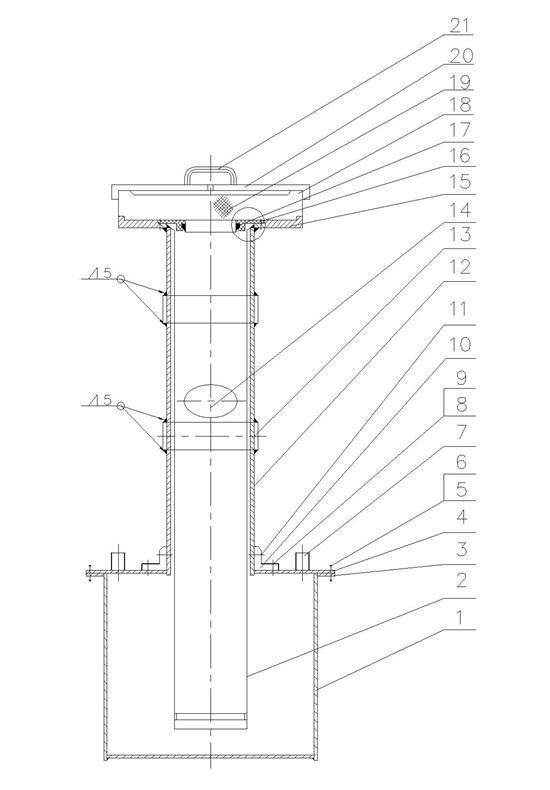

When the accumulated water exceeds the filtering water collection cover, the water will be injected into the sealing system. The water's impact force will flip the butterfly-shaped float ball over. At this time, the collected water will accumulate in the water storage tank. When the water in the water storage tank is full, it will be discharged through the drainage outlet. When the floating roof has no water to discharge, the butterfly-shaped float ball will remain horizontally floating in the sealing system, covering the water seal liquid surface to prevent water evaporation.

Installation Requirements

1. Generally, the lower edge of the single-disc floating roof cover should be 250mm away from the liquid surface inside the oil tank. For the double-disc floating roof, the height from the upper surface of the floating roof to the lower edge of the filter water collection cover is usually 120mm. The installation position should be selected on any unobstructed part of the floating roof.

2. During installation, remove the water seal slot, insert it into the tank through the manhole, install the drainage pipe by inserting it from the top of the floating boat and placing it, and then weld and assemble it together.

3. The designed drainage capacity of this drainage pipe is 40-50 m³/h.

4. Before operation, add 55 kg of water to the water storage tank. When the floating disc rises, add another 45 kg of water. Regularly replenish water during operation to ensure that there is always water in the device.

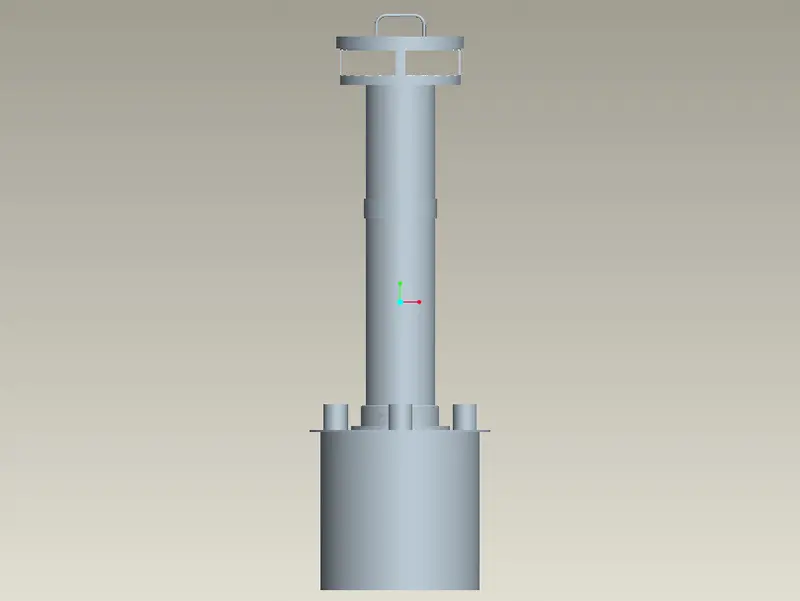

Product Structure Diagram

Specifications

| Companies | Hubei Tianxin Petrochemical Equipment Co., Ltd. |