- All Products

- Hubei Tianxin Petrochemical - Oil Tank Cooling Water Spray Device

Product Introduction

This product has been granted a national patent. Currently, due to long-term exposure to the outside, the gasoline stored in the oil tank is a Class A low flash point flammable liquid with a flash point of -50℃, an upper explosive limit of 6.0%, and a lower explosive limit of 1.3%. Its vapor forms an explosive mixture when in contact with air, and it is highly flammable and explosive when exposed to high heat. In the event of a fire in an above-ground steel storage tank, the tank wall temperature can rise to 500℃ within 5 minutes, reducing the strength of the steel plate by half. After 8 to 10 minutes, the steel plate will lose its supporting capacity. In case of fire in the storage tank, to control the fire and reduce the intensity of flame radiation, it is necessary to spray water on the storage tank in a timely manner for cooling, so that the temperature rise of the tank wall does not exceed 100℃. If the water film adhering to the tank wall is not fully heated and vaporized, the tank wall will not overheat, and the tank's pressure resistance strength can be guaranteed, preventing the accident from escalating.

The design basis of the oil tank cooling water spray device is based on the following specification requirements:

Gb50074-2002 "Code for Design of Petroleum Depots" March 1, 2003

GB50016-2006 "Code for Fire Protection Design of Buildings", July 12, 2006

"Design Fire Protection Code for Petrochemical Enterprises" - July 1, 2009 GB50160-2008

GB50242-2002 "Code for Acceptance of Construction Quality of Building Water Supply, Drainage and Heating Engineering" 2002-02-15GB50242-2002 "Code for Quality Acceptance of Construction of Building Water Supply, Drainage and Heating Engineering" 2002-02-15

Company Background and Product Overview

The oil tank cooling water spray device is the core production line of Honghu Tianxin Petrochemical Equipment Manufacturing Co., Ltd. It integrates an outstanding R&D team, design capabilities, and a continuous production line. It is developed and produced based on market requirements. The oil tank cooling water spray device is all designed and manufactured within the factory. It has the advantages of a short production cycle, advanced equipment, and excellent production environment, which results in a reduction in costs without compromising quality. After being transported to the site, the oil tank cooling water spray device is assembled simply by following the accompanying drawings. There is basically no need for welding at the construction site, thus shortening the installation period, reducing safety hazards, and effectively maintaining the construction environment on site. The oil tank cooling water spray device adopts a brand-new design and a brand-new manufacturing process. Therefore, it effectively increases the product's service life, which can reach over 15 years, significantly reducing the main cost.

Applicable Can Types

Inclined roof tanks, floating roof tanks and spherical tanks

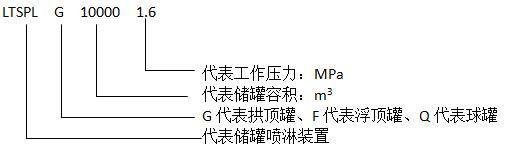

Model Description

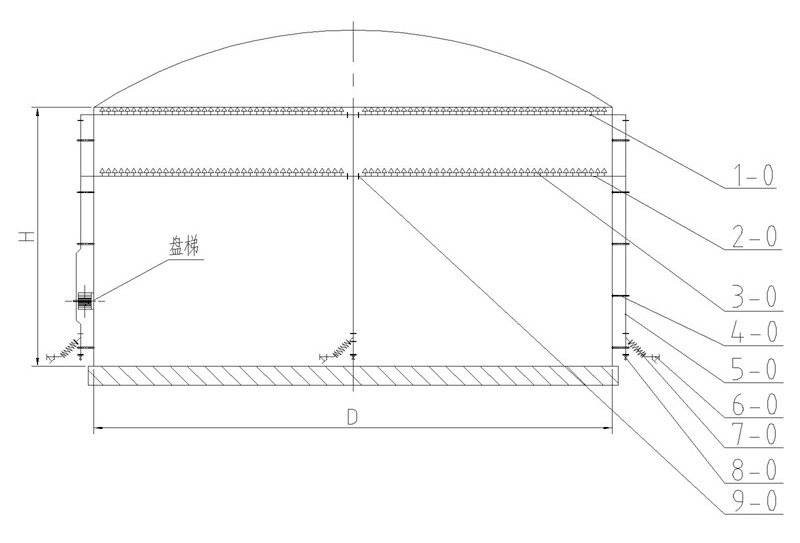

Diagram of the Oil Tank Cooling Water Spray System

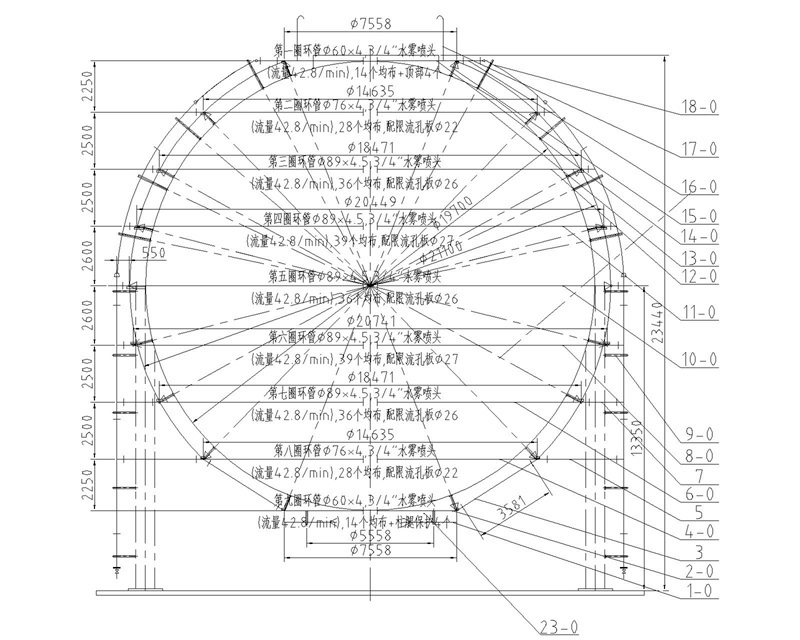

Spray installation drawing for the tank's vertical surface

Product Brief Description

The nozzles are water curtain nozzles or water mist nozzles. The rated working pressure of the nozzles is 0.20 - 0.35 MPa. The spray angle of the nozzles is usually 90° - 120°. Other angles need to be customized. The design spray intensity of the entire oil tank spray system is q2 2.0 L/(minm2), and the design spray intensity of the entire spherical tank spray system is q2 9 L/min.m2. The safety factor is 1.05 - 1.10. The water supply flow rate is the economic supply flow rate of 0.9 m/s to 3.0 m/s.

2. A flow-limiting orifice plate can be installed between the spray ring pipe and the water supply main pipe. Flange connections are used between the ring pipes and between the ring pipes and the main pipes.

3. Install a filter and a metal hose before the water supply main pipe at the water inlet.

4. Provide the tank type and related tank diameter, height and ladder orientation. The factory has designed it anew, providing a design water volume calculation sheet, calculating new parameters, and customizing it to meet specific requirements.

5. Provide the 3C certification certificate of the sprinkler head and relevant performance proof;

6. Provide product quality certificate and heat-dip zinc coating quality inspection report.

Basic Requirements for Customers

Based on the actual working conditions, select the product model that you need the most.

2. Provide the basic parameters of the oil tank, such as the diameter and height of the tank, the specific parameters of the wind-resistant ring and reinforcement ring, and the total water consumption requirement may also be provided.

3. Provide plans and elevation drawings of water supply and drainage pipelines;

4. Provide a diagram showing the orientation of the ladder.

5. Provide requirements for pipe material, fasteners and sealing gaskets;

6. Provide the required water pressure for the pipeline network and the specifications of the pumps.

Specifications

| Companies | Hubei Tianxin Petrochemical Equipment Co., Ltd. |