- All Products

- Hubei Wan'an Environmental Protection - Floating Oil Collection Device

- Model: FD-S50 * 50-W-A

- Origin: Hubei

- Product Overview: This product is mainly designed based on the Archimedes principle of liquid and the vortex properties of liquid, always keeping the oil collection port within a certain depth range of the liquid surface. When the liquid level in the tank changes, the overall device moves up and down around the adapter under the buoyancy of the main float, and maintains a certain depth from the liquid surface to collect surface floating oil or liquid at any time.

- Customized consultation: 027-81948788

Floating oil extraction devices are used in industries such as oil fields, refineries, gas stations, airports, aviation, sewage treatment plants, and smelting. Suitable for the installation and use of crude oil or finished oil tanks, used for oil receiving and delivery operations, further improving the purity of oil products, and preventing the quality of oil products from being affected by impurities at the bottom of the storage tank during oil delivery operations.

1. Product Description

In the process of oil production and storage, a large amount of oily wastewater is inevitably generated, and the wastewater settling tank is one of the main equipment for initial oil-water separation. It collects oily wastewater in the settling tank and then uses the different densities of oil and water to perform initial oil-water separation through gravity settling. During the process of oil-water separation and sedimentation, a large amount of oil-water separation occurs, forming floating oil. The existing sewage tanks and settling tanks only have fixed oil collection tanks at a certain height inside the tanks. When the sewage tank is working, it can only be collected when the oil level is higher than the oil collection tank. When it is lower than the oil collection tank, the oil cannot be discharged, that is, the oil below the oil collection tank cannot be collected completely, and the remaining oil will be discharged together with the discharge of sewage, which poses great difficulties for the subsequent water treatment. Causing significant impact on the environment and economy.

This product is a specialized equipment used in wastewater treatment systems such as oil fields, refineries, and chemical plants to collect floating oil products or upper level liquids from storage tanks or settling tanks. Mainly installed inside tanks with oil-water mixtures or two types of non liquid substances. Used to timely discharge the separated liquid, reduce environmental pollution, and further improve the separation efficiency of mixed liquids.

2. Purpose

This product is a specialized equipment used in wastewater treatment systems such as oil fields, refineries, and chemical plants to collect floating oil products or upper level liquids from storage tanks or settling tanks. Mainly installed inside tanks with oil-water mixtures or two types of non liquid substances. Used to timely discharge the separated liquid, reduce environmental pollution, and further improve the separation efficiency of mixed liquids.

3. Working principle

This product is mainly designed based on the Archimedes principle of liquid and the vortex properties of liquid, always keeping the oil collection port within a certain depth range of the liquid surface. When the liquid level in the tank changes, the overall device moves up and down around the adapter under the buoyancy of the main float, and maintains a certain depth from the liquid surface to collect surface floating oil or liquid at any time.

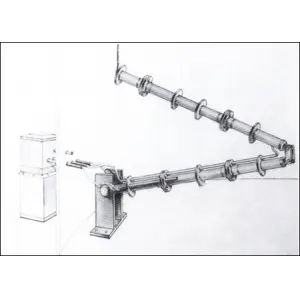

The process principle is shown in the diagram:

(1) When the tank is filled with mixed liquid, the overall device floats up due to the buoyancy of the main float, and at this time, the oil and water are in a mixed state, with the balance float machine's oil collection port at the surface. As shown in Figure (a). Do not drain the oil at this time.

(2) After the sewage enters the tank, due to the different densities of oil and water, gravity settling causes initial separation of oil and water. After oil-water separation, the oil is in the upper layer, forming a floating oil. At this time, the oil collection port is located at the upper end of the oil-water boundary and submerged in the oil layer, and can collect surface floating oil. The location of the oil collection device is shown in Figure (b).

(3) When the upper oil is collected completely and the remaining is sewage, stop draining the oil at this time. The location of the oil collection device is shown in Figure (c)

4. Implement standards

Q/FYH01-2011 "Floating oil collection device"

5. Main technical parameters

1. The device floats up and down with the change of liquid level, collecting the upper floating oil at any time without being limited by the liquid level.

2. Depth from the oil collection port to the liquid level: (20-50mm) (or adjustable according to the process).

3. Liquid density range for collection: ≤ 1.0g/cm3

4. Working liquid level range: approximately 1400-4000mm.

5. Working mode: continuous or intermittent.

6. Design pressure: 1.0Mpa.

7. Work pressure: Normal pressure

8. Operating temperature: 30-50 ℃

9. Other detailed structural dimensions are shown in the accompanying drawings of the equipment.

10. There are a total of 4 oil outlets with a nominal diameter of DN50 and a nominal diameter of DN250.

11. The float can be adjusted up and down.

12. Equipment service life: ≥ 20 years

Specifications

| Companies | Hubei Wan'an Environmental Protection and Petrochemical Equipment Co., Ltd. |