- All Products

- Hubei Wan'an Environmental Protection HB-I Automatic Oil Cut off and Drainage Device

1. Product Introduction

With the development of the national petrochemical industry and the continuous increase of oil storage tank areas, safety, fire prevention, and environmental governance issues have become increasingly prominent. The contradiction between the isolation of tank areas from the outside world and rainwater discharge has long been an unresolved problem. In the past, manual valves and cover plates were generally used to control the discharge of rainwater. When it rained, the valve was opened for drainage, and on sunny days, the valve was closed, which was difficult to operate. After opening the valve on rainy days, there was usually no one to watch over. If an oil leakage accident occurred in the tank area at this time, the oil would flow out of the tank area. Using manual valves for drainage can also drain the remaining oil on the ground with rainwater, which not only wastes oil but also pollutes the environment, and is prone to causing fires. Several major oil tank fires in China have been related to the leakage of rainwater and oil from oil tank areas, causing significant losses to the lives and property of the country and the people. To this end, our company has developed a new generation of HB type automatic oil interception and drainage device for tank areas (patent number: 200520095962.6) based on the requirements of current fire safety regulations for oil storage tank areas in the petrochemical industry, absorbing advanced technologies at home and abroad, and combining our company's experience in oil-water interface control. This product overcomes the shortcomings of the original product and achieves automatic oil interception and drainage, effectively solving the problem of rainwater discharge in the oil storage tank area and preventing oil leakage accidents caused by operational errors, off-duty or control equipment failure in the tank area.

This product meets the requirements of Article 3.2.8 on page 38 of GB50351-2005 "Design Code for Fire Protection Embankment in Storage Tank Areas": "During the research process, the specification preparation team found that the rainwater discharge equipment in many storage tank areas is extremely inadequate... The problem of rainwater discharge in the storage tank area embankment is an important aspect related to safety. In order to completely solve this problem and eliminate the safety hazards caused by it, strict requirements must be put forward in the specification - the storage tank area must be equipped with safe and reliable oil interception and drainage equipment to absolutely avoid oil leakage

This product complies with the provisions of GB50074-2002 "Code for Design of Petroleum Storage" and GB50160-2008 "Code for Fire Protection Design of Petrochemical Enterprises".

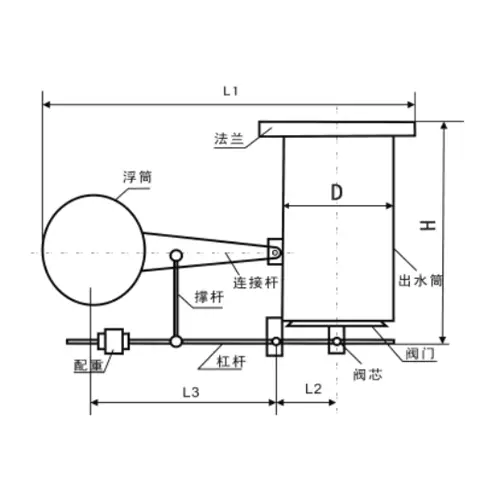

2. Working principle

This product relies on the buoyancy difference of the float in the oil-water medium to achieve oil interception and drainage based on the different densities of oil and water. When there is water in the sand well and it reaches a certain height, the float rises. With a small force, the lever can open the valve and allow the drainage valve to flow into the waterway, which then flows into the outlet cylinder through the outlet valve to achieve pressure reduction. The float continues to rise, and the drainage valve is closed. Water enters the outlet cylinder from the drainage valve. When the medium discharged from the outlet cylinder is oil, the float sinks, and the vent hole of the pressure reducing valve core is closed through the lever, thereby closing the drainage valve and preventing oil overflow. When the weather is dry and there is no water in the sand well, the drainage valve automatically remains closed. When the discharge system of the oil storage tank is in a mixed state of oil and water, the oil and water separate at the sedimentation well, and the lower water is discharged through the drainage valve. The oil is trapped in the sedimentation well, and only the oil in the sedimentation well needs to be collected. Therefore, the complete automation of oil interception and drainage in the oil tank area has been achieved.

3. Product Features

1. This product adopts a special design structure without renal pressure. The lever drives the valve needle to move, so that the pressure inside and outside the valve core is consistent. The lever continues to move, and the needle valve and valve start to drain together flexibly, thus solving the problem of asynchronous pressure reducing valve and drainage valve, overcoming the disadvantage of loose closure, and ensuring the safety of the wet area;

2. No need for any energy to achieve automatic control, safe, environmentally friendly, and economical;

3. Small size, reasonable structure, no vulnerable parts, long service life, no need for water replenishment, easy to use and maintain;

4. When there is water, it automatically opens; when there is no water, it automatically closes; when there is a mixture of oil and water, it automatically separates the oil and water. This equipment works 24 hours a day, reducing the pressure on operators to open and close valves during rainy weather and preventing oil pollution accidents from occurring.

4. Technical parameters

1. Working pressure: ≤0.25MPa

2. Nominal diameter (mm): DN200, DN250, DN300, DN350, DN400, DN500

3. Flange Standard: HG20592-2009

4. Applicable medium density: ≤970kg/m³

Specifications

| Companies | Hubei Wan'an Environmental Protection and Petrochemical Equipment Co., Ltd. |