- All Products

- Hubei Wan'an Environmental Protection - HQSY Type Liquefied Petroleum Gas Automatic Water Cut off Device

1. Product Introduction

The HQSY type liquefied petroleum gas water cut-off device is a new generation product independently developed and designed by our company according to the needs of liquefied petroleum gas water cut-off. It is in a leading position in domestic technology. Compared with similar products in China, it has a reasonable structure, is safe and reliable, is not affected by the pressure inside the tank, does not require external power, and mechanically cuts water. The equipment has a long service life and can be controlled on-site or remotely, achieving a safe and reliable dual safety. In cold seasons, when the water layer at the bottom of the spherical tank is prone to freezing, this equipment can be equipped with an external suction pipe to ensure normal water cut-off.

The liquefied petroleum gas water cut-off device (patent number: 2005009602.9) produced by our company, with its unique water cut-off sealing performance, can ensure that there is no leakage of liquefied gas water cut-off. Whether it is under pressure or under pressure after water cut-off, there is no leakage of liquefied gas in both working conditions.

This product cuts water on the liquefied petroleum gas balloon tank, replacing manual cutting, solving the problem of water leakage and reducing the waste of liquefied petroleum gas. It effectively controls human poisoning and the occurrence of flammable and explosive accidents. Therefore, this product also meets the requirements of system discharge pipeline, avoiding disorderly discharge and improving the ecological environment.

This product has been strictly tested and approved by the labor department, and its design, manufacturing, and acceptance fully comply with the following standards and specifications:

1. Safety technical regulations for containers: "Supervision Regulations for Safety Technology of Pressure Vessels";

2. GB/T50183-2004 "Code for Fire Protection Design of Petroleum and Natural Gas Engineering";

3. Design, materials, manufacturing, testing and acceptance conditions: GB150-1998 "Steel Pressure Vessels";

4. Paint, packaging and transportation related standards: JB/T4711-2000 "Coating and Transportation Packaging of Pressure Vessels".

2. Working principle

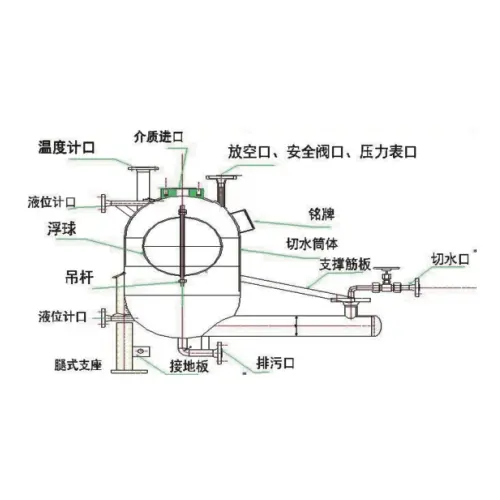

This product consists of the main components of the water cutter, including the housing, float, lever, buoyancy amplification mechanism, and arrow free secondary sealing valve. It utilizes the principle of the density difference between water and liquid, as well as the pressure of the liquid in the container, to achieve up and down movement by immersing the float in the buoyancy difference between water and liquid. The buoyancy amplification mechanism amplifies the buoyancy difference, thus controlling the opening and closing of the pressure free valve as power, and quickly returning the separated liquid light in the water cut-off tank to the spherical tank, thus achieving the purpose of water cut-off control.

This product can also be equipped with a control system (including emergency shut-off valves for remote monitoring systems, signal processing parts, monitoring displays, etc.) according to user needs. In the control room, it can monitor the cutting of water from multiple tanks, implement emergency opening and closing, and make the liquefied petroleum gas cutting water pipe physical and chemical.

3. Technical characteristics

1. Design pressure:

2. 2MPa~6.4MPa

3. Working temperature: 1 ℃~50 ℃

4. Working medium: liquefied petroleum gas liquids and water

5. Medium density: ≤ 790kg/m ³

6. Cutting capacity: 5-20t/h

7. Cut water hydrocarbon content: ≤ 20PPM

8. Voltage of instrument self-control alarm system: DC24V

Specifications

| Companies | Hubei Wan'an Environmental Protection and Petrochemical Equipment Co., Ltd. |