- All Products

- Hubei Wan'an Environmental Protection - Oil containing Sewage Cyclone Separation Device

1. Technical development background

As most domestic oil fields enter the late stage of secondary and tertiary extraction, the fluidity and heavy content of crude oil are becoming increasingly severe. On the one hand, with the acceptance of tertiary oil recovery technology, the difficulty of dehydration and cutting points has greatly increased; On the other hand, the complex situation of the interweaving of crude oil produced water and oil in water in China, as well as the addition of large amounts of polymers and chemical agents during the oil recovery process, greatly increases the difficulty of crude oil dehydration and cutting, seriously affecting the trend of heavy and heavy refining in refineries.

The heavy and difficult to cut point transformation of crude oil, especially oxidation separation, seriously affects the realization of safe and stable production in refineries, resulting in greater difficulty in operating the primary distillation tower unit for oil and gas, especially the occurrence of deoxygenation at the cut point of oil and water. The problem of oil and water cut back has become an urgent need for domestic refining enterprises. The reasonable solution of certain oil and water cut back devices has greatly increased the amount of heavy oil, wash oil, and processing losses in refineries. Almost all domestic refining enterprises have encountered serious oil and water cut back problems, and the direct consequence is the increasingly poor quality of oil products.

Domestic refining enterprises generally still use the "old three sets" technology for sewage treatment, namely "sedimentation, oil separation, flotation, and biochemistry". The advantage of this technology is lower ore production; The disadvantage is that it occupies a large area, has poor oil-water separation effect, and cannot effectively remove dissolved oil, emulsified oil, and dispersed oil from sewage. With the increasing proportion of heavy and low-quality crude oil blending and the intensification of emulsification of oily wastewater, this facility can no longer meet the requirements of clean production.

Therefore, in the context of increasingly high environmental protection requirements and high crude oil prices, conducting research on comprehensive treatment technology for oily wastewater in oil blending units, developing new types of wastewater and sewage treatment equipment, can effectively recycle and utilize crude oil resources, reduce processing losses of the units, and achieve standard discharge of wastewater from the units, reducing the impact and secondary pollution of oily wastewater on subsequent sewage treatment plants. The economic and social benefits will be significant.

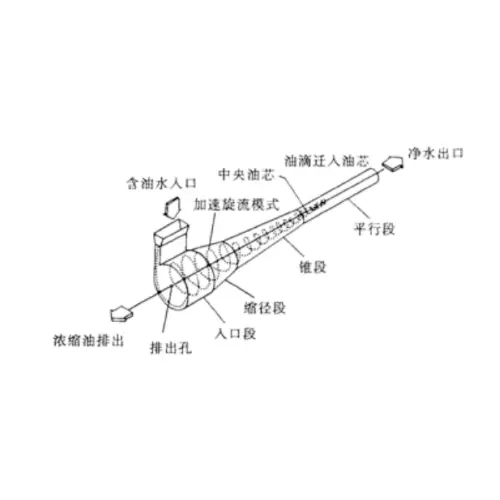

2. Introduction to Cyclone Separation Technology

Cyclone separation technology is widely regarded as an efficient and energy-saving separation technology, and its key component is the cyclone separator, abbreviated as the cyclone. Cyclones can be used for separation processes such as clarification, thickening, water cutting, grading, washing, etc. of heterogeneous mixtures such as liquid, liquid-solid, gas/liquid-liquid, liquid-solid, liquid-liquid, etc. The cyclone separator has a simple structure, no moving parts, low manufacturing cost, reliable operation, low maintenance cost, low energy consumption, small space occupation, high efficiency, wide application, and no pollution. The promotion of cyclone separation technology is of great significance for increasing efficiency, saving energy, reducing environmental pollution, and improving social and economic benefits.

The technical characteristics of cyclone diversion technology can be summarized as follows:

(1) Simple structure, compact equipment, and small footprint;

(2) Low cost (including manufacturing costs, maintenance expenses, and energy consumption);

(3) Easy to install (the cyclone can be installed at any angle);

(4) Simple operation, reliable work, and convenient maintenance;

(5) High separation efficiency and strong degree of automation (continuous operation, easy cleaning, and easy implementation of automation);

(6) Good adaptability, wide applicability, and versatile range for various situations (parallel connection can increase production capacity, series connection can improve product quality, and operating temperature and pressure are not limited).

Cyclone separation technology, as an efficient and energy-saving technology, mainly separates oil, liquid (such as water and aqueous systems), gas, and gas-liquid solid multiphase systems, and its application range is extremely wide. Compared with oil removal technology, cyclone oil removal technology has the advantages of compact structure, small volume, light weight, high oil removal efficiency, no moving parts, long service life, and a closed and pollution-free process.

3. Industrial application conditions

1. Oil and water cutting operation parameters for atmospheric and vacuum distillation unit (provided)

(1) Cutting capacity: maximum 60t/h, 50t/h, 30t/h, average 20t/h, minimum 10t/h.

(2) Cut water temperature: 70 ℃~90 ℃.

(3) Oil content: maximum 10000mg/l, normal 350mg/l, minimum 30mg/l.

(4) Feed density: 0.928-0.8585g/cm ³.

(5) Cut water pressure: 1.0MPa before the cooler and 0.6MPa after the cooler.

2. Design indicators for industrial experimental equipment for sewage energy flow separation

(1) Feed pressure: 1.0MPa

(2) Processing capacity: 3.5t/h

(3) Cut water temperature: 70 ℃~90 ℃

(4) Feed oil content:<10000mg/l

(5) Total pressure drop (drainage):<400Mpa

(6) Purified water oil content:<400ppm

(8) Return tank dirty oil (including water): 0.28t/h

Specifications

| Companies | Hubei Wan'an Environmental Protection and Petrochemical Equipment Co., Ltd. |